High-Power Connectivity with Busbar Solutions by Yazaki Innovations

From early concept to mass production, our team helps you design and manufacture busbars that unlock better performance, manufacturability, and total cost of ownership.

Solution Overview

We support everything from simple formed and stamped busbars to complex 3D formed for high-voltage battery packs and power electronics. Our global engineering and manufacturing footprint helps OEMs and Tier 1s launch scalable, repeatable, and high-quality busbar systems, faster.

Key use cases include:

- Off-road and construction equipment power distribution

- Agriculture equipment

- EV battery pack and module interconnects

- Energy storage (BESS) and industrial power solutions

Frequently Asked Questions

-

What are busbars and why are they important?

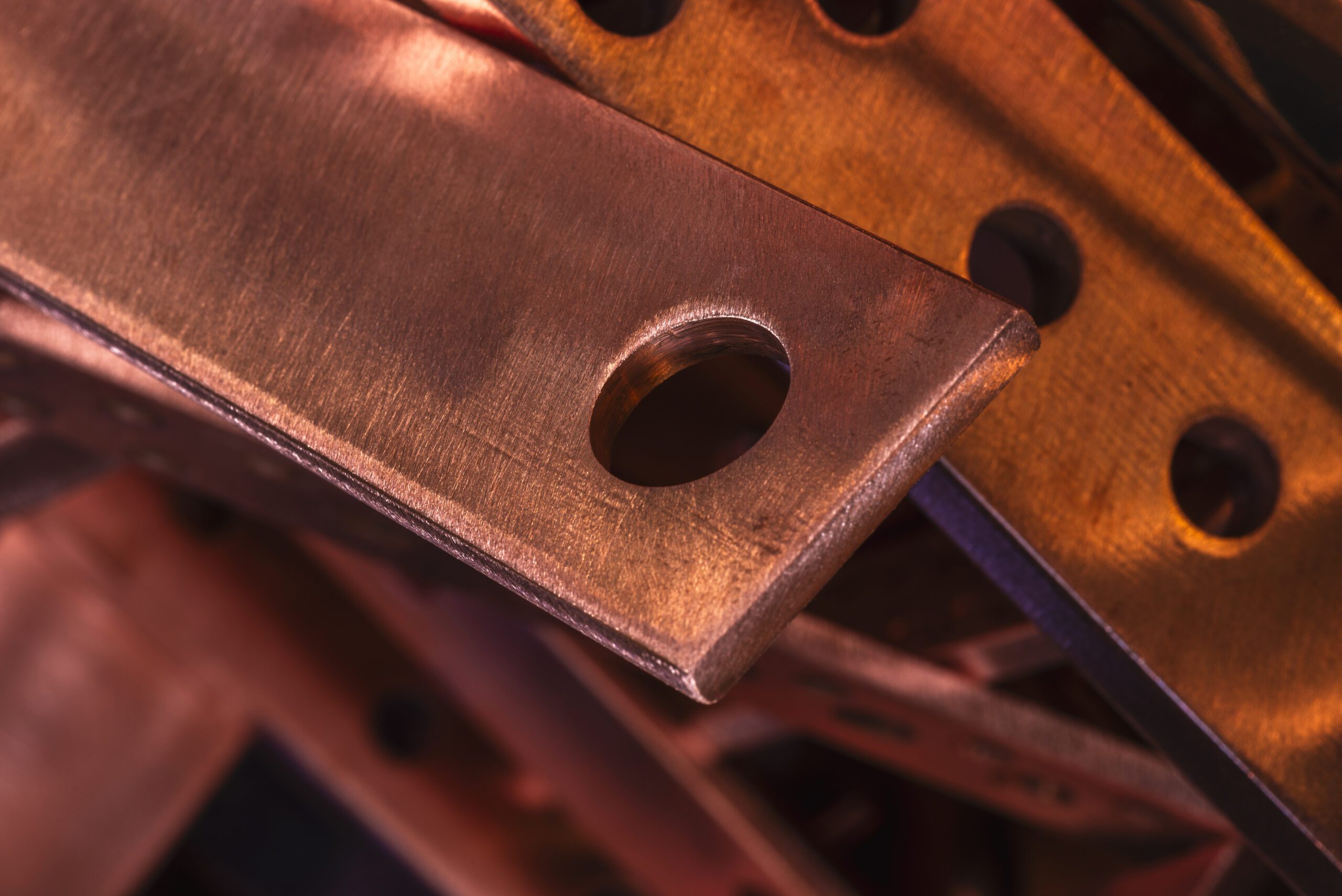

Busbars are rigid or flexible conductors, typically copper or aluminum, used to safely carry and distribute electrical power within a system. Compared to traditional cable harnesses, busbars can handle higher current in a more compact, robust, and repeatable package, making them ideal for EV batteries, power electronics, and high-power industrial applications.

-

How do busbars differ from traditional cables?

Cables are round, flexible conductors that are cut and terminated individually, often leading to variation and complexity during assembly. Busbars use flat conductors with defined geometry, clear mounting points, and consistent spacing. This geometry improves thermal performance, reduces inductance, and simplifies installation, especially in high-voltage, high-current environments.

-

What types of busbars can Yazaki Innovations provide?

We offer a range of solutions, including:

- Stamped and formed copper/aluminum busbars

- Insulated busbars for high-voltage safety and pack integration

- Plated busbars (e.g., tin, nickel, silver) for improved corrosion resistance and contact performance

-

Which industries and applications do you support?

Our busbar solutions are designed for:

- Electric vehicles (passenger, commercial, and specialty)

- Off-road and construction equipment

- Agriculture and heavy machinery

- Energy storage systems (BESS)

- Industrial power distribution and backup systems

If your application requires safe, compact, and high-power distribution, we can help! -

Can you support custom designs and prototypes?

Yes. Our engineering team collaborates closely with your design, battery, and power electronics teams to create custom busbar concepts, 3D models, and prototypes. We support iterative development, design reviews, and validation activities to accelerate your path to production.

-

What materials and plating options are available?

We work primarily with copper and aluminum in various alloys and tempers, selecting the best option based on current, weight, and cost targets. Plating options include tin, nickel, silver, and other finishes tailored to your corrosion, conductivity, and contact requirements.

-

How do you ensure quality and reliability?

Busbars are manufactured in controlled environments with robust process controls, inspection, and testing. We offer:

- Dimensional and visual inspection

- Electrical and insulation resistance testing

- Thermal and environmental validation

Our goal is to provide consistent, repeatable performance for every part number and production lot. -

Can busbars help reduce system size and weight?

Yes. By optimizing conductor geometry and routing, busbars can reduce packaging volume compared to bundled cables and complex connectors. This helps OEMs shrink battery packs and power modules, improve energy density, and reduce total system mass.

-

Where is your busbar manufacturing facility?

Our busbars are all manufactured in our El Paso, Texas facility.

-

How do I get started with Busbar Solutions?

Contact us with your program requirements, such as voltage level, current rating, packaging constraints, and target start of production. Our team will work with you to:

- Review your system architecture

- Propose busbar concepts and materials

- Develop prototypes and cost estimates

- Build a roadmap from pilot to full production